Series 3D

The 3D series pumps is a general purpose design suitable for many applications including lubrication, fuel transport and burner service, low pressure hydraulic applications and hydraulic elevator service. Pump shaft is generously sized to allow belt drive if desired (mechanical seal versions only).

This series is available in magnetic drive configurations.

Size |

||||||

106 |

||||||

118 |

||||||

137 |

||||||

156 |

||||||

187Y |

||||||

187M |

||||||

187 |

||||||

218L |

||||||

218 |

||||||

250P |

||||||

250 |

||||||

275E |

||||||

275 |

||||||

312P |

||||||

312 |

||||||

337 |

||||||

350 |

||||||

400P |

||||||

400 |

||||||

Series 3D Specifications

Casing- High tensile, close-grained cast iron. Cast steel optional, sizes 156-400

Rotor Housing- Pearlitic gray iron

Power Rotor- Alloy steel, nitride hardened and thread ground

Idler Rotors- Pearlitic gray iron, induction hardened and thread ground

Gaskets- Cellulose and non-asbestos fiber

Seal & Bearing- Type B: Buna N bellows mechanical seal, Buna N o-rings and standard external, permanently grease packed, deep groove ball bearing- recommended for distillate fuels and lubricating oil or hydraulic fluids. Type H: Positive drive mechanical seal, fluoroelastomer o-rings and external high temperature, permanently grease packed, deep groove ball bearing.

Accessories- Completely mounted, built to order pump/driver assemblies are available with baseplates, ANSI RF spool pieces, NEMA 'C' face adapters.

Outlet Pressure- 500 PSIG (34.5 BAR) maximum. Minimum recommended differential pressure is 40 PSI (2.75 BAR).

Inlet Pressure- Type B & H: 75 PSIG (5 BAR) maximum, distillate fuel, lube- sizes 106-187. 50 PSIG (3 BAR) maximum, distillate fuel, lube- sizes 218-400. Type H: 40 PSIG (2.7 BAR) maximum, residuals and crude oil- sizes 106-187. 10 PSIG (0.7 BAR) maximum, residuals and crude oil- sizes 218-400.

Viscosity- 33 SSU (2.0 CST) minimum. Type B: 3000 SSU (650 CST) maximum (consider cold start). Type H: viscosities above 3000 SSU (650 CST).

Temperature- Type B: 0 to180°F (-18 to 82°C). Type H: 0 to 250°F (-18 to 121°C) at 1800 RPM or less, 0 to 225°F (-18 to 107°C) above 1800 RPM.

Drive- Direct, belt or chain. Sealless magnetic Drive configurations also available.

Rotation- Clockwise facing pump shaft standard. Consult Imo for counterclockwise

Mounting- May be foot mounted in any orientation. Flange mounting optional for horizontal or vertical installations.

Filtration- Inlet strainers are required to keep contaminants and abrasives out of the pump. They must be selected in consultation with the strainer vendor to prevent pump starvation. Normally, 60 mesh (0.01 inch- 238 micron) for light and 1/8-3/16 inch (3-5mm) openings for heavy oils are recommended.

Maximum Speed- Do not exceed 1800 RPM pumping residual fuels or crude oil due to the presence of abrasives and contaminants.

| Size | 106 | 118 | 137 | 156 | 187 | 218 | 250 | 275 | 312 | 337 | 350 | 400 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5000 | 5000 | 4400 | 4400 | 4400 | 3600 | 3600 | 3600 | 2500 | 2500 | 2500 | 2500 |

* Assumes minimum inlet pressure requirements are met.

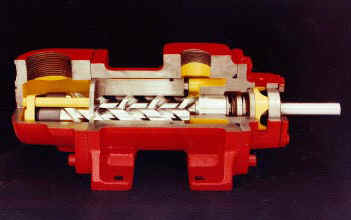

G3DB-187 shown with replaceable rotor housing (liner), single mechanical seal and external ball bearing.