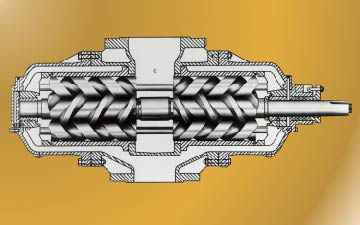

Series 323F

Series 323F is a double suction design providing the highest flow rates of any three screw pump. They are found in tank farm services, loading and unloading terminals, power plants and asphalt process and transfer.

323F SERIES |

Nominal flow rate, GPM/LPM, at 300 PSI (20.7 BAR), 200 SSU (43 CST) |

||||

SPEED RPM |

|||||

Size |

1150 |

960 |

870 |

720 |

690 |

550J |

944/3574 |

761/2882 |

675/2553 |

530/2006 |

501/1897 |

550 |

1314/4972 |

1070/4048 |

954/3611 |

761/2882 |

723/2736 |

630M |

1728/6540 |

1407/5326 |

1255/4750 |

1002/3791 |

951/3599 |

800J |

3063/11595 |

2500/9463 |

2233/8453 |

1789/6770 |

1700/6433 |

Series 323F Specifications

Casing- High tensile gray cast iron. Optional steel casing available. A 150 PSIG (10.3 BAR) steam/hot oil jacket available on steel cased pumps.

Rotor Housing- Cast gray iron.

Power Rotor- Alloy steel.

Idler Rotors- Pearlitic ductile (nodular) iron.

Gaskets- Cellulose and non-asbestos fiber.

Seal & Bearing- Type P: Alternate rows of hard and soft square molded packing rings. Type B: Buna N bellows mechanical seal with carbon on niresist faces. Type H: Positive drive mechanical seal with carbon on niresist faces. Recommended for residual and crude oils. All types have two internal sleeve bearings.

Accessories- Completely mounted, built to order pump/driver assemblies are available with baseplates, ANSI RF spool pieces, etc.

Outlet Pressure- 300 PSIG (20.7 BAR) maximum. Minimum recommended differential pressure is 40 PSI (2.8 BAR). Consult Imo Pump for higher pressures.

Inlet Pressure- 25PSIG (1.7BAR) maximum.

Viscosity- Type P: 100 to 25,000 SSU (20 to 5400 CST). Type B: 50 to 3000 SSU (8 to 650 CST). Consider cold startup conditions. Type H: 50 to 20,000 SSU (8 to 4300 CST). Consult Imo Pump for lower or higher viscosity operation.

Temperature- Type B: 0 to 180°F (-18 to 82°C). Type H and P: 0 to 250°F (-18 to 121°C)

Drive- Direct only.

Rotation- Clockwise facing pump shaft .

Mounting- Horizontal foot mount Optional vertical mounting available for certain applications.

Filtration- Inlet strainers are required to keep contaminants and abrasives out of the pump. They must be selected in consultation with the strainer vendor to prevent pump starvation. Normally, 60 mesh (0.01 inch- 238 micron) for light and 1/8-3/16 inch (3-5mm) openings for heavy oils are recommended.

Maximum Speed*- 1200 RPM

* Assumes minimum inlet pressure requirements are met.